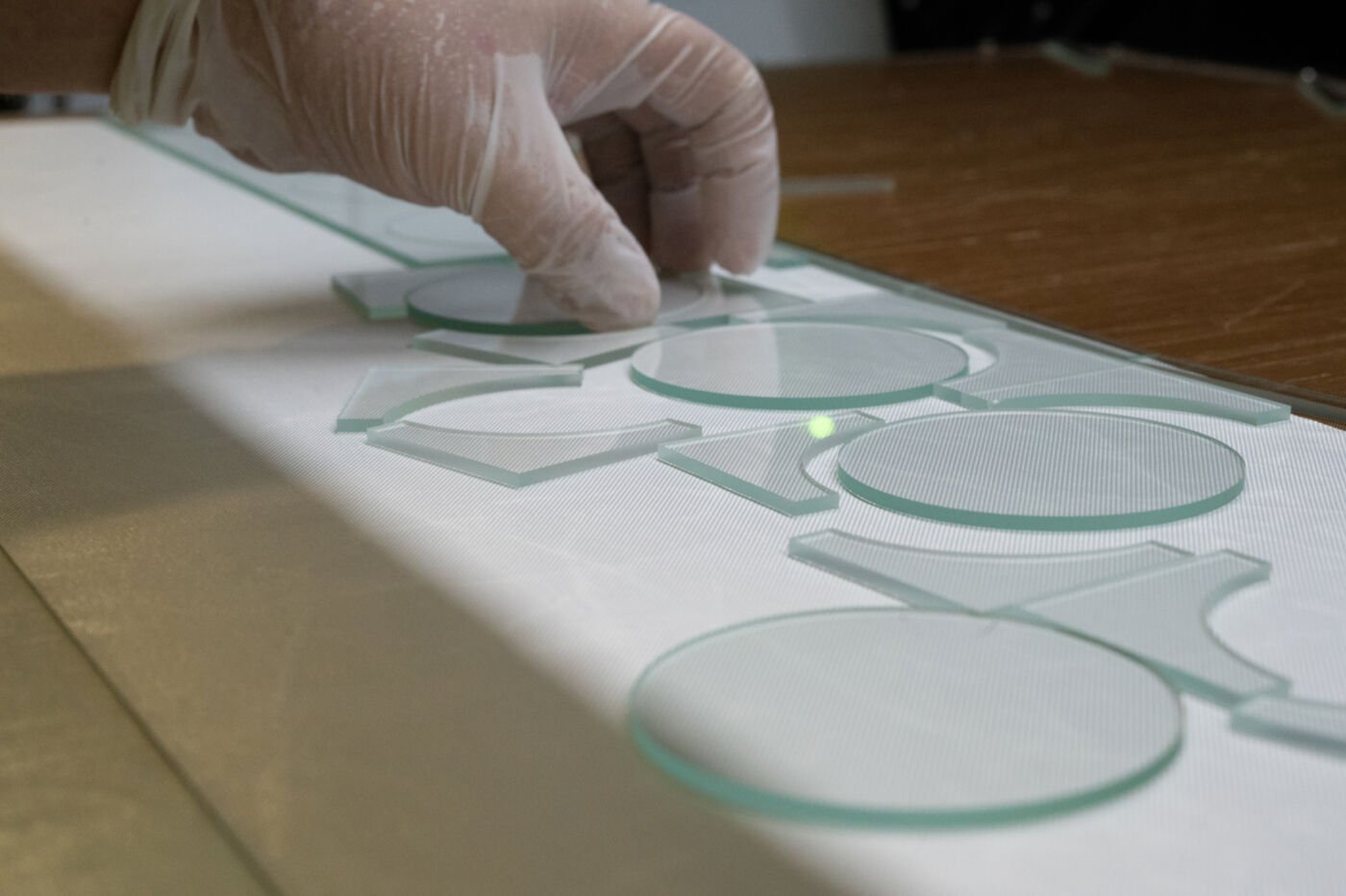

Cover Glass and Display Lens

Optical Filters manufactures a bespoke range of cover glass and plastic lenses for electronic displays tailored to suit your application's aesthetic and functional requirements. These display filters can be supplied as individual components, as part of a display or touch screen assembly.

Plain Glass

Plain float soda-lime glass is a rugged cost-effective solution for cover lenses and Projective Capacitive Touchscreens (PCAP), it can be CNC processed to size, shape, and edge finish with options of printing and chemical tempering. Other glass types such as Borosilicate and alkali-aluminosilicate, such as Gorilla glass, are also available.

Anti-Glare Etched Glass

Anti-Glare (AG) glass is not coated, it is chemically etched to achieve a scatter of reflected light. Although the glass surface reflectivity is not reduced, the matte texture induces scattering of the reflective image, making it indistinguishable, therefore reducing the glare. AG glass is a practical selection for the touchscreen user interface and outdoor displays.

Anti-Reflective Glass

Anti-Reflective (AR) glass is more commonly used for display applications that require readability; primarily cover glass applications. The glass is coated with a highly durable multi-layer thin film which reduces surface reflectivity from approximately 4% through a mechanism of destructive interference.

Anti-Reflective/Anti-Fingerprint Glass

Anti-Reflective/Anti-Fingerprint (AR/AF) glass is a coated product for applications where an AR finish is required for reduction of reflectivity and the front surface is used as a touch interface. The AF coating drastically reduces finger oil transfer making cleanup of surface residues easier.

The addition of the AF coating does not degrade the AR optical performance; thus, the AR/AF combination is a durable and practical solution for touch screen interfaces with high-end optical requirements.

Anti-Reflective/Anti-Glare Glass

Anti-Reflective/Anti-Glare (AR/AG) glass is a combination coated product of AG with a multi-layer thin AR coating providing a surface reflectivity of less than 0.4%. The coating is additionally scattered so no distinguishable reflected image can be observed. AR/AG glass is the highest performing front surface finish for display assemblies needed in the most difficult display viewing environments, including full sunlight conditions.

Chemical Toughening

The glass is chemically strengthened by an ion exchange process. Chemical toughening is a versatile option that can be applied to glass starting at 0.5mm thickness and results in up to 4 times the mechanical strength of annealed glass, but without the optical and physical distortion that can come with thermal toughening.

Acrylic

This light weight plastic offers many of the benefits of glass, such as high optical clarity and excellent scratch resistance, while remaining easy to machine in complex shapes. In addition to transparent clear material, we offer colored materials for contrast enhancement and diffusion filters for LCD back lights. These filters can also be supplied with silkscreen printing or self-adhesive tape for easy, effective installation. The cover lens can be purchased in both gloss and non-glare (NG) finish.

Polycarbonate

Polycarbonate provides high impact resistance combined with an excellent flammability rating, unlike the acrylic filter. While comparable to glass in many ways, polycarbonate is suitable for applications where weight is an important consideration as it is a much lighter substrate. Optical Filter’s polycarbonate sheets are available in a range of thicknesses and surface finishes. Because polycarbonate is easily scratched due to softness, Optical Filters recommends a clear hard coating preferably on both the front and rear surfaces; hard coat is available in gloss, non-glare (matte anti-glare), AR, as well as AR/AF. This coating will provide a high level of chemical resistance while eliminating the risk of scratching as a result of general handling.