Our Process and Capabilities

For more than thirty-five years, Optical Filters have been capitalizing on our extensive experience in optical design and development in order to continuously offer innovative solutions to improve and protect display function and durability.

Built on trust and dependability, our customer relationships are strong and collaborative from start to finish on each project.

Production

- To support our objectives, meet our customers’ growing needs, and improve reliability, we continue to bring previously outsourced processes in-house by committing to expanding our manufacturing facilities in North America and the United Kingdom.

- With the ability to handle a range of quantities, our production is flexible, built to order, and includes rapid prototyping alongside volume orders.

- We continue to invest in new technologies and people to deliver quality, on-time display enhancement products and services.

Material Processing Capabilities Include:

- X-Y CNC machine and laser cutter for thin films, polarizers, and EMI filters

- Plastic CNC processing for polycarbonate, acrylic sheets and laminates

- Precision glass cutting table for large specifications

- Latest glass laser CNC for complex shapes cut to very tight tolerances

- Glass CNC profiler for automated finished bevel edges

- Silk screen printing, logos on both glass and plastic

- Semi-automated application of Ag busbar and heater wire

Optical Lamination Capabilities

- Enlarged and improved clean rooms

- Wide range of dry film optical lamination methods

- PSA/OCA lamination of filters and touch films

- Proprietary Viz-Bond® liquid bonding for displays and optical stacks

- Dry film optical bonding for displays and touchscreens

- LCD bonding equipment to accommodate bezel-less displays

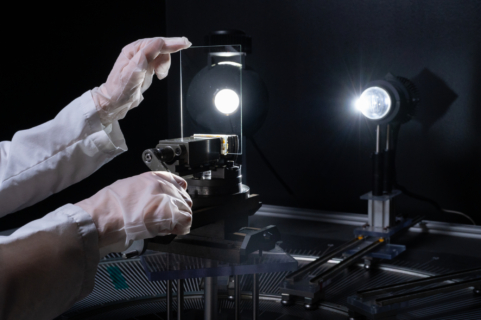

Testing and Measurement Capabilities Include:

- Photopic reflectance and contrast ratio testing

- Temperature, humidity, and solar radiation testing

- Ball drop and boot kick impact testing