RFI and EMI Shielding

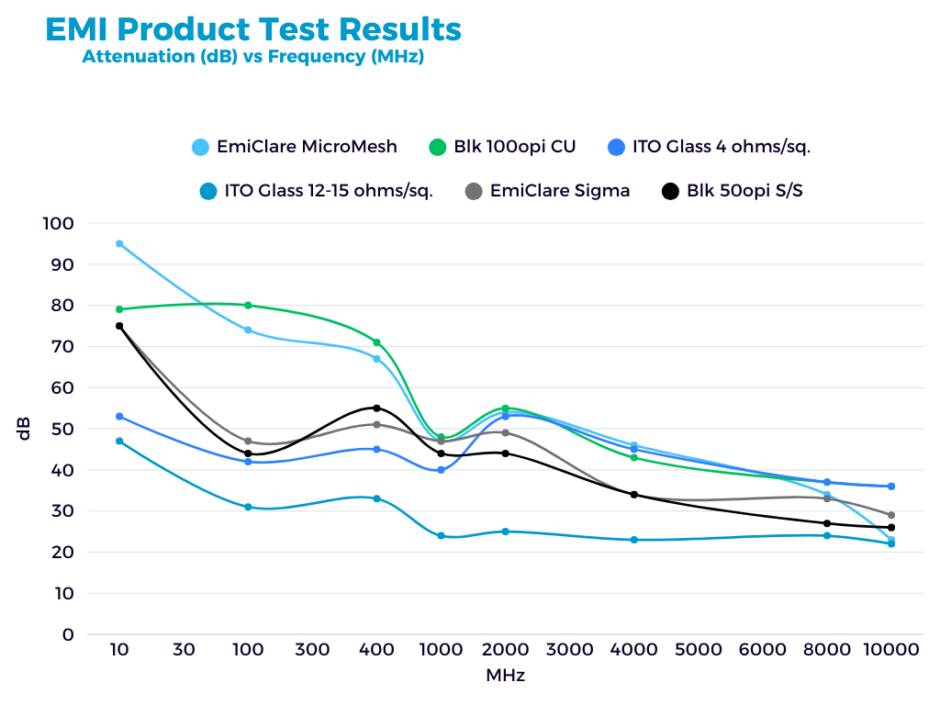

Optical Filters are specialists in Electro Magnetic Interference (EMI) and Radio Frequency Interference (RFI), developing our own line of mesh and using conductive coatings, woven wire mesh, and micro-replicated conductive grids to protect products.

While every application has its own balance of optical requirements and shielding attenuation, we can find the ideal EMI/RFI shielding solution for your industry.

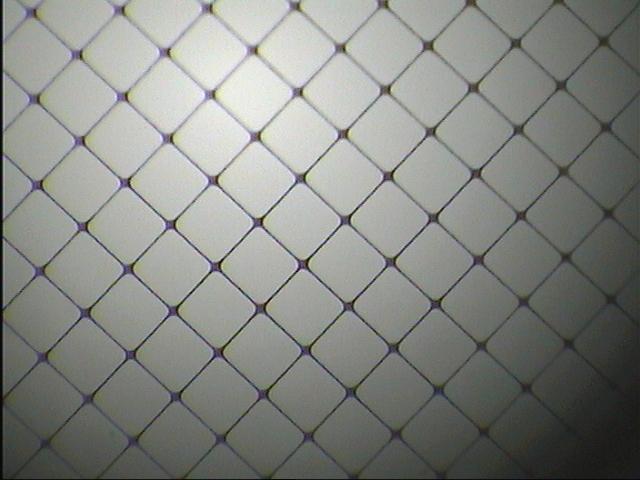

EmiClare® MicroMesh®

EmiClare is an unconventional mesh specifically designed by Optical Filters for optical clarity without compromising the Electromagnetic Interference (EMI) shielding efficacy. A perfect photo-etched highly conductive grid, it is the result of Optical Filters’ continued research and development program to attain the best combination of optical appearance and shielding effectiveness.

With a range of micro-replicated conductive grids, woven wire mesh, and conductive coatings, EmiClare is designed for allowing optical clarity without Electro-Magnetic Compatibility (EMC) compromise. The shielding also makes your display or touchscreen Radio Frequency Interference (RFI) compliant. Ideal for display sizes up to 60", Micromesh offers the optimal combination of high shielding attenuation and light transmission available.

Key Features and Benefits:

- Excellent optical performance with moiré optimized configuration

- Very low surface resistance supports high shielding effectiveness

- Superior light transmission and sunlight readability

- Wide range of integration options and substrates to create the optical stack that meets your needs

EmiClare® Sigma

A fully laminated polycarbonate window for EMI shielding electronics, displays, and apertures where light transmission, optical clarity and shielding performance are important.

EmiClare Sigma has a unique woven wire grid specifically developed for use on flat panel displays. The configuration of the wire grid has been optimized for less image distortion and higher light transmission, creating brighter, more readable displays. The conductive blackened wire is embedded between layers of polycarbonate, ensuring EMI/RFI shielding performance.

Key Features and Benefits:

- Pre-laminated standard panel range covers several thicknesses, surface finishes, and mesh angles

- Cost-effective solution with short delivery times

- The laminated UL94 rated polycarbonate is both light and durable

- CNC machined to final size, EmiClare Sigma can be supplied with holes, complex forms, and stepped edges

EmiClare TCF

EmiClare TCF is a low resistance, electrically conductive, silver alloy coated, optically clear polyester EMI/RFI shielding film. The combination of high visible light transmission, near neutral colour, infrared heat rejection, and low electrical resistance make EmiClare TCF an ideal EMI/RFI shield for electronic displays, touchscreens, and membrane switch panels requiring moderate shielding effectiveness and high-quality optical properties. This thin film is a clear choice for integration into optical stacks and displays.

EmiClare TCF is a replacement material to the discontinued EMI-ITO15 coated film.

Key Features and Benefits:

- Low surface resistance options of 4 or 12 ohm/sq

- Robust and flexible PET base film

- High visible light transmission

- High IR reflectivity

- Reduced discoloration compared to discontinued ITO coated film

- Ag alloy has a high resistance to oxidation

- The conductive coating can be etch patterned

Available from stock in rolls, sheets or as custom cut parts.

EMI-ITO Coated Glass

EMI-ITO coated glass is a single-sided, conductive, coated, plain float glass for use in EMI/RFI shielding applications. The glass can be combined with options from our inventory, including anti-glare, anti-reflective and other surface finishes.

- Standard spluttering coating densities of ≤5ohm/sq or 12–15ohm/sq

- Repeatable, consistent, line coated glass in a master sheet size of 850x550 mm

- Single glass thickness of 1.1mm and 2.2mm or fully laminated construction

High transmission conductive coatings available from stock for quick cost-effective availability.

Woven Wire Mesh

Traditional woven wire meshes of blackened copper and blackened plated stainless steel for legacy applications, large, shielded windows, and stand-alone open apertures.

Optical Filters’ mesh blackening is highly conductive and processed for demanding optical applications. We can provide cut parts, framed filters, glass and plastic lamination as well as supply rolls and sheets.

| p/n | Material | Finish | Format/Dimensions | Transmission @ 550nm | Sheet Size |

|---|---|---|---|---|---|

| SWA-SS-BLK-50@30 | 50opi 0.0012” stainless steel woven wire with a 30’ bias angle | Blackened Conductive Cu plated | 600mm (24”) x 450mm (18”) | 82% | 600 (24") 450 (18") |

| SWA-SS-BLK-50@45 | 50opi 0.0012” stainless steel woven wire with a 45’ bias angle | Blackened Conductive Cu plated | 600mm (24”) x 450mm (18”) | 82% | 600 (24") 450 (18") |

| SWA-SS-BLK-50@90 | 50opi 0.0012” stainless steel woven wire with a 90’ bias angle | Blackened Conductive Cu plated | 600mm (24”) x 450mm (18”) | 82% | 600 (24") 450 (18") |

| SWA-SS-BLK-80@30 | 80opi 0.0012” stainless steel woven wire with a 30’ bias angle | Blackened Conductive Cu plated | 600mm (24”) x 450mm (18”) | 70% | 600 (24") 450 (18") |

| SWA-SS-BLK-80@45 | 80opi 0.0012” stainless steel woven wire with a 45’ bias angle | Blackened Conductive Cu plated | 600mm (24”) x 450mm (18”) | 70% | 600 (24") 450 (18") |

| SWA-SS-BLK-80@90 | 80opi 0.0012” stainless steel woven wire with a 90’ bias angle | Blackened Conductive Cu plated | 600mm (24”) x 450mm (18”) | 70% | 600 (24") 450 (18") |

| SWA-SS-BLK-100@30 | 80opi 0.0012” stainless steel woven wire with a 30’ bias angle | Blackened Conductive Cu plated | 600mm (24”) x 450mm (18”) | 64% | 600 (24") 450 (18") |

| SWA-SS-BLK-100@45 | 100opi 0.0012” stainless steel woven wire with a 45’ bias angle | Blackened Conductive Cu plated | 600mm (24”) x 450mm (18”) | 64% | 600 (24") 450 (18") |

| SWA-SS-BLK-100@90 | 100opi 0.0012” stainless steel woven wire with a 90’ bias angle | Blackened Conductive Cu plated | 600mm (24”) x 450mm (18”) | 64% | 600 (24") 450 (18") |

| SWA-CU-BLK-100@90 | 100opi 0.002” copper woven wire with a 90’ bias angle | Blackened Conductive Oxide | 600mm (24”) x 600mm (24”) | 60% | 600 (24") 600 (24") |

| SWA-CU-BLK-100-ROLL | 100opi 0.002” copper woven wire with a 90’ bias angle | Blackened Conductive Oxide | 2m wide roll x sq/mtr | 60% | 2 mtr wide roll x sq/mtr |

Shielding